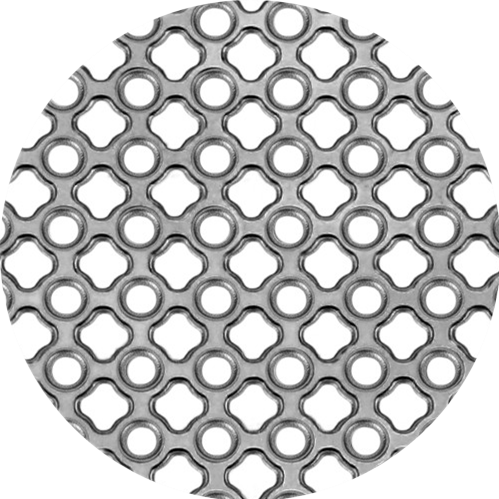

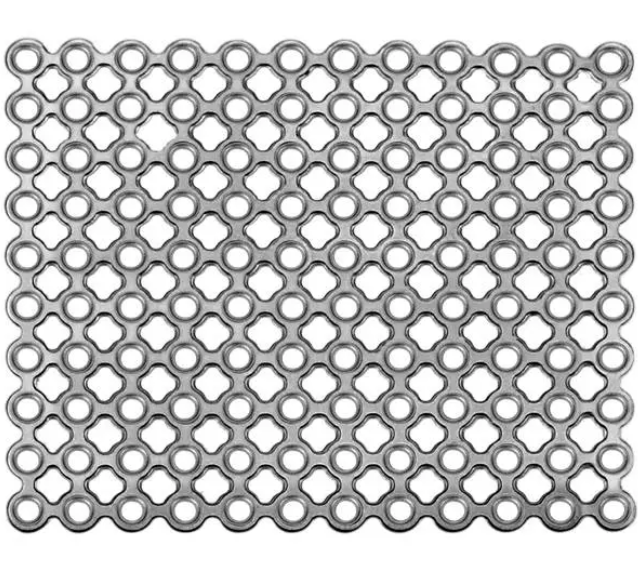

Flat Titanium Mesh-2D Round Hole

Flat Titanium Mesh – 2D Round Hole

Utilization

Designed for neurosurgical reconstruction and restoration, cranial defect repair, and support in medium- to large-scale cranial reconstruction.

Material

Triple-smelted medical-grade titanium, optimized for surgical applications.

Key Features & Benefits

-

Rib Reinforcement: Enhanced plasticity and hardness without compromising flexibility.

-

High Biocompatibility: Excellent corrosion resistance and stable chemical properties.

-

Radiological Safety: Non-magnetic; safe for CT, MRI, and Η-ray imaging.

-

Post-Operative Integration: Fibroblasts can grow into mesh pores, enabling seamless integration with surrounding tissue.

-

Durability & Flexibility: Extremely strong yet lightweight. No fracture or sharp breakage under repeated bending (tested to withstand ten 180° double bends without pause).

-

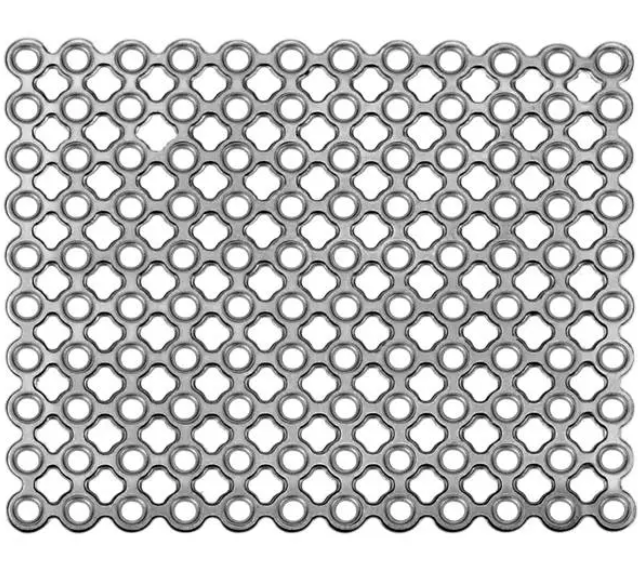

Precision Manufacturing: Proprietary optical etching ensures equal-sized holes, uniform spacing, and smooth edges for better modeling and safer use.

-

Minimal Deformation: Will deform generally under force but avoids localized fractures, minimizing risk of re-injury.