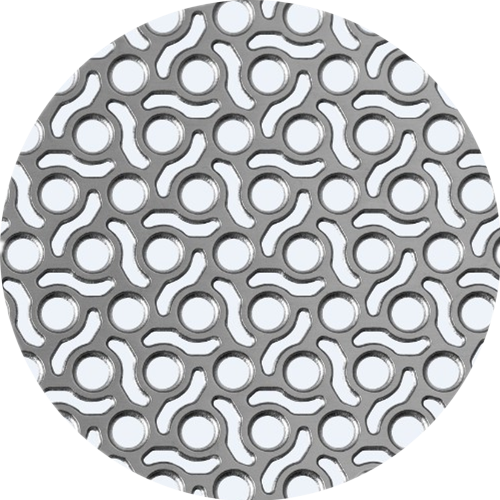

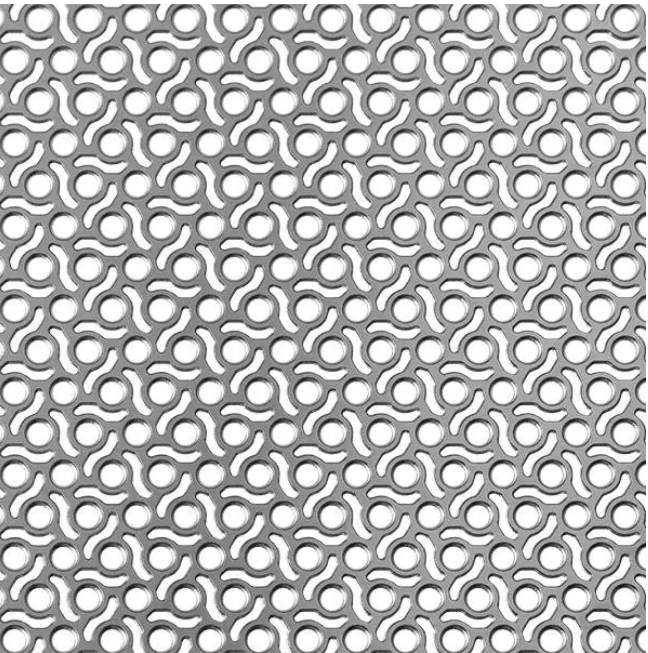

Flat Titanium Mesh-3D Flower Shape

3D Titanium Mesh for Cranial Reconstruction

Application: Neurosurgical use for cranial defect repair and medium- to large-scale skull reconstruction.

Material: Medical-grade titanium (triple-smelted), quality-checked through five inspections. Final check: 180° bend repeated 10 times without fracture.

Specifications (mm):

-

60×80

-

80×120

-

90×90

-

100×100

-

100×120

-

120×120

-

120×150

-

150×150

-

150×180

Key Features:

-

Elliptical Hole Design: Ensures full contact with bone while avoiding deformation issues of standard meshes.

-

Enhanced Malleability: Moderate hardness, excellent extensibility, and easy modeling—ideal for complex cranial shapes.

-

Rib Reinforcement: Improves strength and flexibility; supports intraoperative or preoperative shaping.

-

Optimized for Complex Areas: Effective on large or curved skull regions.

-

In-house Optical Etching: No machining required; provides smooth, precisely spaced holes with consistent mesh integrity. Mesh only deforms as a whole under external force—no local breakage.

Compatible Screws:

-

Ø1.5 mm self-drilling screw

-

Ø2.0 mm self-drilling screw

Recommended Tools:

-

Mesh scissors (cable cutter)

-

Mesh forming pliers

-

SW0.5×2.8×75 mm cross-head screwdriver